Innovation thrives when we tend to achieve a clear understanding of customer and market needs. By actively getting market insights, we can develop innovative products, services, or features that meet or exceed customer satisfaction.

Bosuer is very clear about market changes. It focuses on continuous research and development efforts by analyzing market dynamics and user needs to identify gaps or emerging opportunities.

With our own racing team, we verifies its mass-produced products on the competition field. This helps to achieve the most accurate data about the product application and users’ needs in the field. In this way, the R&D team continuously optimizes their own products so their performance can reach the best level.

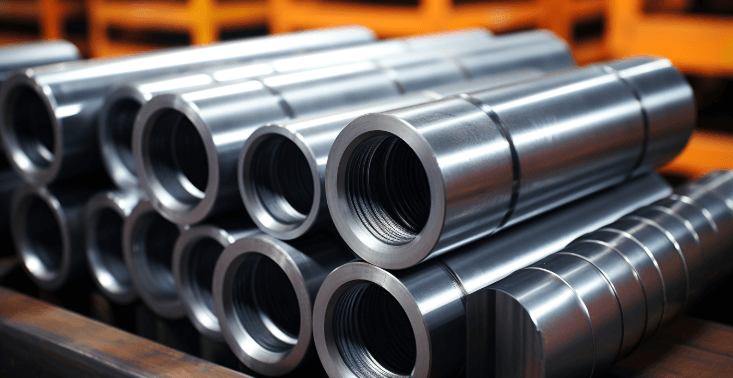

Advanced materials can enhance performance by reducing weight, improving agility, and increasing durability to withstand rugged terrains. This focus on innovation offers a competitive edge in a market where superior performance is key.

Bosuer has taken an innovative approach by fundamentally upgrading the materials and technologies used in their off-road motorcycle frames. This strategy reflects our commitment to providing riders with motorcycles that excel in demanding off-road environments.

Off-road motorcycles are subjected to rough terrains and high impacts. Low-quality frames cannot withstand these extreme conditions, hence compromising safety and performance. Bosuer goes the extra mile to ensure safety, durability, and performance by using high-end materials.

The R&D team takes full benefit of the standout feature of aluminum alloy, “memory function.” This material shows deformation when a certain force is applied but returns to its original shape once the external force is removed. Unlike steel, this feature ensures that the frame maintains its structural integrity and shape even after encountering impacts on rough terrains.

Bosuer also uses another high-grade material with exceptional strength, tensile resistance, and fatigue resistance in the manufacturing of its frames. This special material (Chromium molybdenum steel) is better than other non-ferrous materials in the market as it contributes to the overall performance and longevity of the motorcycles, setting them apart from the competitors.

Bosuer has implemented new processes in the production of off-road motorcycle frames to revolutionize the manufacturing process.

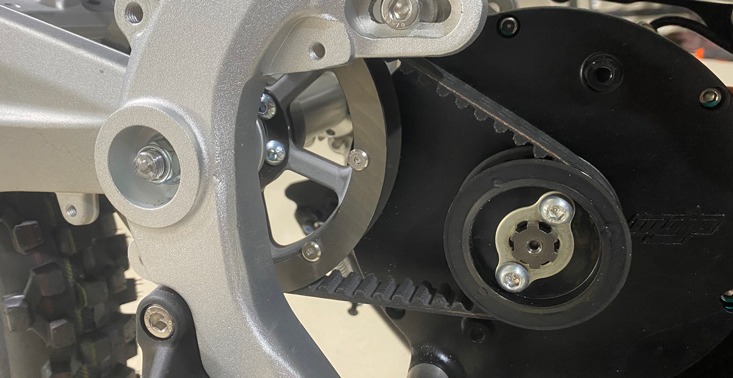

To make the manufacturing process efficient, the in-house manufacturing process of Bosuer is characterized by the use of welding robots. Robot welding offers higher efficiency and aesthetically consistent welds as compared to manual welding, which the competitors use. This results in top-quality and durable frames for off-road motorcycles.

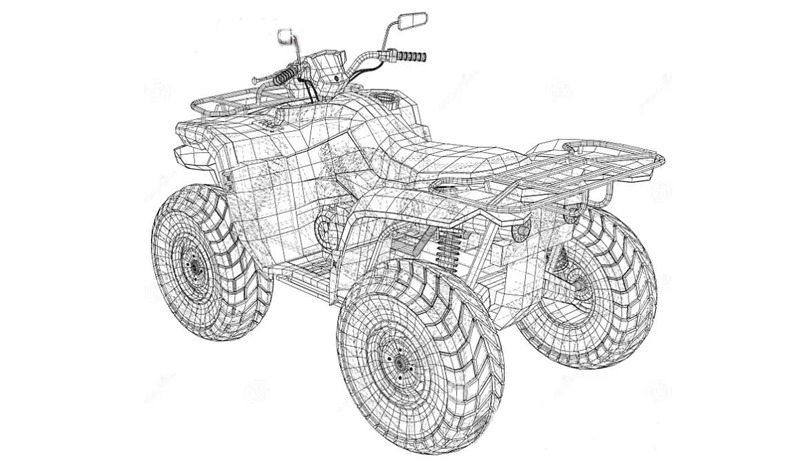

Innovative R&D in product application for off-road motorcycles involves a structured process from initial ideation to rigorous trials to ensure high performance. Here’s a breakdown of each stage.

Concept development for off-road motorcycle manufacturing is a strategic and visionary process. It is the initial step that involves defining the core idea behind a cross-country motorcycle and determining specific factors that will set it apart.

The market research helps in identifying the target audience and their expectations. Then, the key features of the product are determined. For a cross-country motorcycle, the brand identifies features like lightweight, versatility, high performance, exceptional agility, powerful engines, and durability for rough terrains.

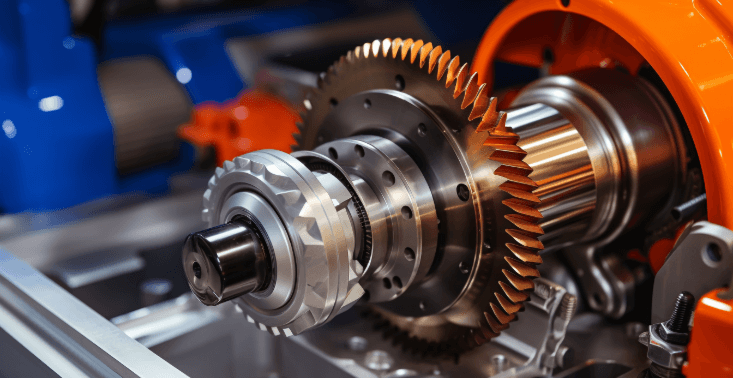

The next step in product development is the system design, which is defining the configuration of systems and components in the off-road motorcycle to meet the performance and functionality goals.

For a motorcycle, the system design consists of:

Weight distribution| Suspension|Ergonomics|Safety features

For an off-road racing bike, the bike is designed to be lightweight with a suspension system that absorbs shocks, is easy to maneuver, and provides control with brakes for safety.

After the determination of the system design, the detailed design phase starts, which includes the planning of specific components and their attributes. It includes:

Before introducing the product in the market, it undergoes rigorous testing to identify any areas of improvement. Off-road motorcycles go through the following tests:

When the product passes the testing in the factory, it is introduced in the field in a controlled environment.

Like in the off-road industry, motorcycles are tested on the field through various competitions to check their performance in off-road conditions.

Bosuer in-house motorcycle Racing Team also participates in application testing of the latest technologies and functions to ensure safety and performance for real riders.

The innovative research and development efforts by Bosuer have yielded exceptional achievements in the off-road motorcycle industry. Based on 22 years of experience, the R&D team has formed unique internal structures, appearances, and designs. It has also continuously upgraded its products since its inception.

Bosuer R&D department is focused on highlighting performance and configuration to enhance the off-road motorcycling experience. The brand has experimented with different techniques to generate products that have premium features, getting a competitive edge over other competitors.

Bosuer has formed a very comprehensive product line in the industry. Every year, new products are launched, providing customized and diversified choices to the users. Our products, like electric balance scooters, electric dirt bikes, etc., are selling well in the global market. Some well-established products are:

Our R&D team upgraded engine power significantly. The 250cc engine has a power of up to 19.8 kilowatts compared to other competitors that offer 12-13 kilowatts, which makes engines more stable and high-performing.

The meticulous attention to the internal engine configurations such as pistons, spark, and plugs (specifically NGK) for better stability and combustion makes their engine different from others. The internal structure of the engine gives the following benefits: