Dirt bikes are designed for off-road riding on rough terrain like mud and rocky paths. They’re built to be fast, agile, and durable for riding in challenging environments.

But if you’re like me, the first question that would pop into your head would be — how does a dirt bike engine work?

After all, a bike’s engine is its heart. If you want to figure out its true potential and performance, understanding the engine is the way to go. So, in today’s post, let’s discuss this topic in great detail. Dive in!

Which Dirt Bike Engine is Right for You: Two-Stroke or Four-Stroke?

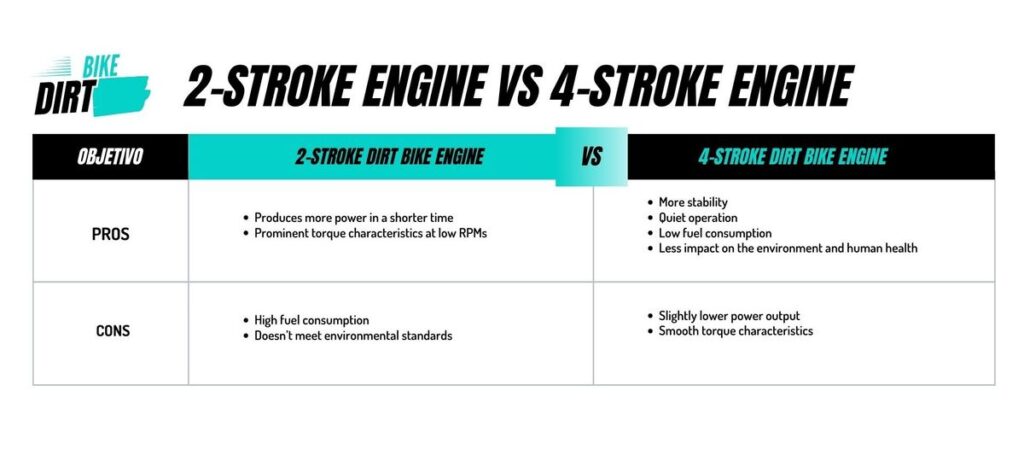

Dirt bikes are powered by gasoline engines that use either a two-stroke or four-stroke cycle. The 4-stroke dirt bike engine is generally preferred by most riders because of its stability and lower vibration rate.

Two-Stroke Engines: High Power in a Compact Package

The dirt bike engine 2 stroke works by moving the piston up and down twice. However, in each cycle, the spark plug ignites and the crankshaft rotates only once.

So, while the mixture is compressed in the first stroke, it is ignited in the second – driving the piston to work. This particular mechanism allows for a relatively smaller and lightweight structure that produces higher power output.

But there’s one catch. These engines use a mixed fuel (gasoline and engine oil), which results in higher emissions and fuel consumption. It also creates more vibration, so you won’t find it ideal for long rides.

2 stroke dirt engines are known for their poor exhaust system too. This makes them extremely noisy.

Four-Stroke Engines: Smooth Performance and Efficiency

This engine for dirt bikes is more complex than 2 stroke one. It has four strokes – intake, compression, power, and exhaust. In each work cycle, the crankshaft rotates twice.

However, the main action occurs in the 3rd stroke (power). This is when the air-fuel mixture is ignited, which pushes the piston down and converts internal energy into mechanical energy. As a result, you get to enjoy good fuel economy and lower emissions.

You also get more stability, less vibration, and quieter operation. This is why most people and manufacturers prefer this engine type for dirt bikes. It works excellently for both short and long-distance riding.

What is Dirt Bike Engine Displacement?

“CC” or cubic centimeters is the unit of measurement used for displacement, which is the volume of gas the engine can intake in one revolution. So, if a dirt bike has a larger displacement, it can release more energy and produce more power.

However, it also means the bike consumes more fuel. To help you understand better, here is an overview of different dirt bike engine displacements and their characteristics:

50cc dirt bike engine

Also called a mini dirt bike engine, it has the lowest power output. However, it’s easy to handle and lightweight. You will find it to be ideal for beginners or children who are learning.

70cc dirt bike engine

The 70cc is slightly more faster and powerful than 50cc. New learners can use it to practice off-roading on various terrains including forest trails and desert dunes.

125cc dirt bike engine

This displacement results in moderate power and good acceleration as well as off-road performance. It’s suitable for intermediate riders who want to try riding on various terrains.

250cc dirt bike engine

250cc dirt bikes are known for their high power and excellent off-road performance. It even has some capability for on-road biking, which makes it the most preferred option among professionals.

300cc dirt bike engine

The 300 cc dirt bike engines are the perfect compromise between power, weight, and versatility. It has more power and torque which allows riders to maintain higher speeds and better control on more demanding trails.

450cc and above dirt bike engine

This is considered to be the top-tier, premium displacement that is capable of handling most toughest conditions. Whether you want to try off-road or on-road biking, this displacement will help you deliver an outstanding performance.

How Does a Dirt Bike Engine Work?

A dirt bike engine works by using either a two-stroke or four-stroke cycle to force a fuel and air mixture into a combustion chamber, igniting it, and then using the resultant explosion to propel the bike forward. Here’s a detailed explanation of how exactly does this happen:

Intake

The process begins with the intake stroke. As the piston moves downward in the cylinder, it creates a vacuum that opens the intake valve. This allows a precise mixture of fuel and air to enter the combustion chamber.

The ratio of this mixture is critical for efficient combustion. In carbureted engines, the fuel and air are mixed in the carburetor before entering the cylinder. However, in fuel-injected engines, fuel injectors spray fuel directly into the air stream as it enters the chamber.

Compression

Next comes the compression stroke. Once the fuel and air mixture is inside the combustion chamber, the piston moves back up and closes the intake valve.

This upward motion compresses the mixture into a smaller space within the cylinder, which increases its pressure and temperature. Compression is important because it makes the fuel-air mixture more volatile and ready for ignition.

The degree of compression directly influences the power output of the engine; the more the mixture is compressed, the more explosive the combustion will be.

Combustion

At the peak of the compression stroke, the spark plug fires and ignites the compressed fuel-air mixture. The resulting explosion forces the piston back down with great force, which is known as the power stroke.

This downward motion of the piston is where the engine generates its power. The energy from the explosion is transferred through the piston to the crankshaft, converting the linear motion into rotational motion that drives the bike’s wheels.

This is the most critical phase in the engine cycle, as it directly produces the mechanical energy needed to move the bike.

Exhaust

Finally, the cycle completes with the exhaust stroke. As the piston rises again, it opens the exhaust valve, allowing the burnt gases from the combustion process to be expelled from the combustion chamber.

These exhaust gases are pushed out of the cylinder through the exhaust valve and exit via the exhaust system. This step is essential to clear the chamber for the next cycle. It ensures that the engine can continuously repeat the process efficiently.

As the piston moves up, it also rotates the crankshaft, which continues to transmit power to the rear wheel through the bike’s transmission system.

9 Main Components of a Dirt Bike Engine

Piston

The piston is one of the core components of the dirt bike engine. It moves back and forth in the cylinder. It also works with the cylinder and valves to complete the intake, compression, combustion, and exhaust processes.

Remember that the piston’s quality affects the engine’s power and lifespan. That’s why they are typically made from high-strength aluminum alloy. The material offers good wear resistance and high-temperature performance.

Cylinder

The cylinder houses the piston and forms the combustion chamber where fuel burns to produce power. It also features multiple cooling fins to increase heat dissipation area. This ensures the engine doesn’t overheat during high-load operation.

Crankshaft

The purpose of a crankshaft is to convert the piston’s reciprocating linear motion into rotational motion. It transfers power to the transmission and rear wheel through gears at one end. So, it should have enough strength and rigidity to withstand such forces during operation.

Valves

Valves are devices that control the flow of a fluid or gas. In a dirt bike engine, these valves regulate the air-fuel mixture at different speeds and loads. This ensures the intake and exhaust processes take place perfectly.

Camshaft

The camshaft is a small shaft used to control the valve operation. It helps the valves rotate and achieve precise results.

Spark Plug

As the name suggests, a spark plug is useful for generating an electric spark in the engine. It ignites the air-fuel mixture to produce power through combustion.

Ignition System

The ignition system includes all the dirt bike engine parts that are necessary to provide high voltage to the spark plug. Although each system is designed a bit differently, the main items in it include ignition coil, stator, flywheel, and CDI unit.

Cooling System

Since the engine produces so much heat, the cooling system is installed to provide a passage for heat regulation. It moves the coolant around the engine to remove heat and ensure normal working temperatures.

Lubrication System

The lubrication system includes the oil pump, oil filter, and oil passages. Its purpose is to lubricate the different engine parts and reduce overall wear and tear.

How to Choose a Good Engine For Your Off-Road Motorcycle?

While understanding your engine’s mechanism is important, it’s not useful in determining how well it will perform. If you are looking for the best dirt bike engine in the market, you should know about the following indicators:

Displacement

Displacement refers to the engine’s capacity to intake air and fuel in one complete cycle, measured in cubic centimeters (cc). A higher displacement usually means the engine has more power and better acceleration.

You should choose the displacement according to your skill level. Beginners should opt for 50cc to 70cc dirt engine bikes, whereas intermediate should go for 125cc to 250cc ones. Advanced riders should go for bikes above 300cc.

Maximum Power

Maximum Power represents the highest output the engine can achieve at a particular speed. An engine with higher maximum power will allow the bike to reach high speeds more quickly. If you’re also curious about how fast different off-road motorcycles can reach, check out our article How Fast Do Dirt Bikes Go?

Furthermore, when evaluating maximum power, consider your riding style and intended use. For racing or riding on challenging terrains where speed is important, opt for an engine with higher maximum power.

This will allow you to accelerate quickly and maintain higher speeds. However, if you’re a beginner or plan to ride on less demanding trails, you may not need the highest power available, as it can make the bike harder to control.

Maximum Torque

Maximum Torque measures the engine’s ability to deliver force, especially at low speeds. High torque is beneficial for hill climbing and initial acceleration. It makes the bike more responsive and easier to handle in tough conditions.

So, if you plan to do high-force tasks like climbing steep hills, go for higher torque like 40 Nm (Newton-meters) or higher.

Compression Ratio

Compression Ratio describes how much the air-fuel mixture is compressed in the cylinder before ignition. A higher compression ratio generally leads to more power but may require higher-quality fuel to prevent engine knocking.

When determining a good dirt bike engine, consider the trade-off between power and fuel requirements. If you’re looking for maximum performance and are willing to use premium fuel, a higher compression ratio (12:1 to 14:1) is advantageous.

However, if fuel cost and availability are concerns, an engine with a moderate compression ratio might be a more practical choice.

Engine Speed

Engine Speed, measured in revolutions per minute (rpm), indicates how quickly the engine can operate. Higher engine speeds can provide better performance and efficiency but may also lead to increased wear and tear.

So, if you plan to ride competitively, an engine that can handle higher RPMs may be ideal. For recreational riding, an engine that operates efficiently at lower RPMs might offer better longevity.

How to Maintain Your Dirt Bike Engine?

Two-stroke dirt bike engines usually last for 100 to 200 hours, while four-stroke dirt bike engines last up to 500 hours. However, if you maintain them properly and regularly, you can use them much longer.

One of the most important tasks is regular oil changes. Think of oil as the engine’s lifeblood – it lubricates, cleans, and cools the engine. Over time, the oil’s effectiveness decreases, so change it regularly (along with the oil filter) to keep your engine running smoothly.

Another key aspect is engine chain maintenance. The chain needs to be properly lubricated and adjusted to ensure it functions efficiently. Regular cleaning and lubrication prevent rust and wear while checking the tension helps avoid transmission issues.

Also, don’t forget about the air filter that protects your engine from dust and debris. Keeping the filter clean and replacing it when necessary ensures that only clean air enters the engine. This prevents damage and keeps the engine in its original condition.

Lastly, but most importantly, the cooling system, ignition system, and engine fasteners must be regularly inspected. These parts are what mainly help the engine function. So, make sure the coolant is sufficient and everything else is secure.

If you find signs of rust, corrosion, or any other damage, get it repaired immediately to prevent further damage. Also, always refer to the maintenance manual specific to your dirt bike model, as it provides detailed guidance on keeping your engine in top shape.

However, if you’re completely new to dirt bike engines, consider a professional service to help you maintain your dirt bike engine.

Wrap It Up

All in all, understanding how a dirt bike engine works is important to maximize its performance and lifespan. By learning about the engine’s components, how to evaluate its quality, and the best maintenance practices, you’re well-equipped to keep your dirt bike in top shape.

If you’re a dirt bike dealer or looking to upgrade your dirt bike team with high-quality motorcycles at competitive prices, Bosuer (BSE) is your best choice. As a leading off-road motorcycle manufacturer, Bosuer specializes in producing high-performance four-stroke dirt bikes.

Our dirt bike engines feature durable aluminum alloy pistons, efficient cooling systems, and robust crankshafts for optimal power transfer. Whether for professional racing or enthusiast riding, Bosuer dirt bikes deliver the perfect balance of power, performance, and durability for all off-road challenges.